Custom Metal Casting - 3D drawings/prints to Metal

I've been interested in metal casting for a few years now, casting one-off's for projects here and there. I feel the quality of my raw castings is good enough for other tinkerers and inventors to make use of this service.

Whether you need an obsolete car part reproduced, a custom manifold for that gadget you are working on or a custom gearbox housing for that e-bike project - We can work together to bring your design to life!

Send me an email (BennVenn (at) hotmail.com) and we can discuss your project. Due to the size and weight of cast aluminium parts, this service is probably best suited to Aussies - unless you're happy to pay the shipping costs.

What will this cost you? My intention is to increase my skills and quality and hopefully turn this into a business. But for now, If you cover the costs of Gas, Filament, Scrap metal and buy me a beer, I'll be happy!

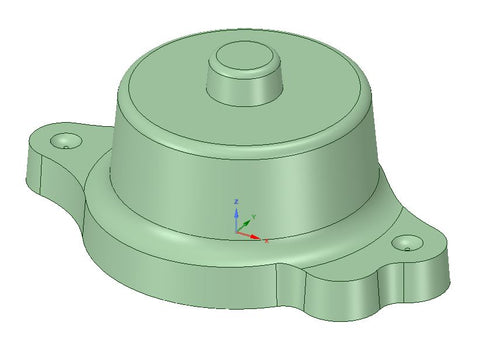

Step1: Design the part in CAD

Step2: 3d print the part to form a sand casting pattern. There are some design considerations with sand cast patterns. All vertical edges must have a draft angle to help remove the pattern from the sand. This is typically 3-5degrees. Any complex voids must be made with a specialised core, or post casting machining.

Step3: Cast the part. This is typically what a raw casting looks like. There must be a way for the molten metal to enter the mold, this is with the sprue. This needs to be considered in the design phase. Also, vents, gates and minimum wall thickness's are important.

Step4: If the client requests, some simple machining operations can be made to clean up the casting, drill holes, tap threads, increase clearances to spec etc...

Custom parts for model steam/IC engines.

Fuel injected manifold for an old Air cooled, VW beetle engine.

With the use of cores, complex voids can be included into the casting.

This is a 2 part casting, a High pressure refrigerant receiver for an ORC system

With a 12mm CNC cut Perspex sight glass

Send me an email! I'm always interested to hear about other tinkerers projects and designs!